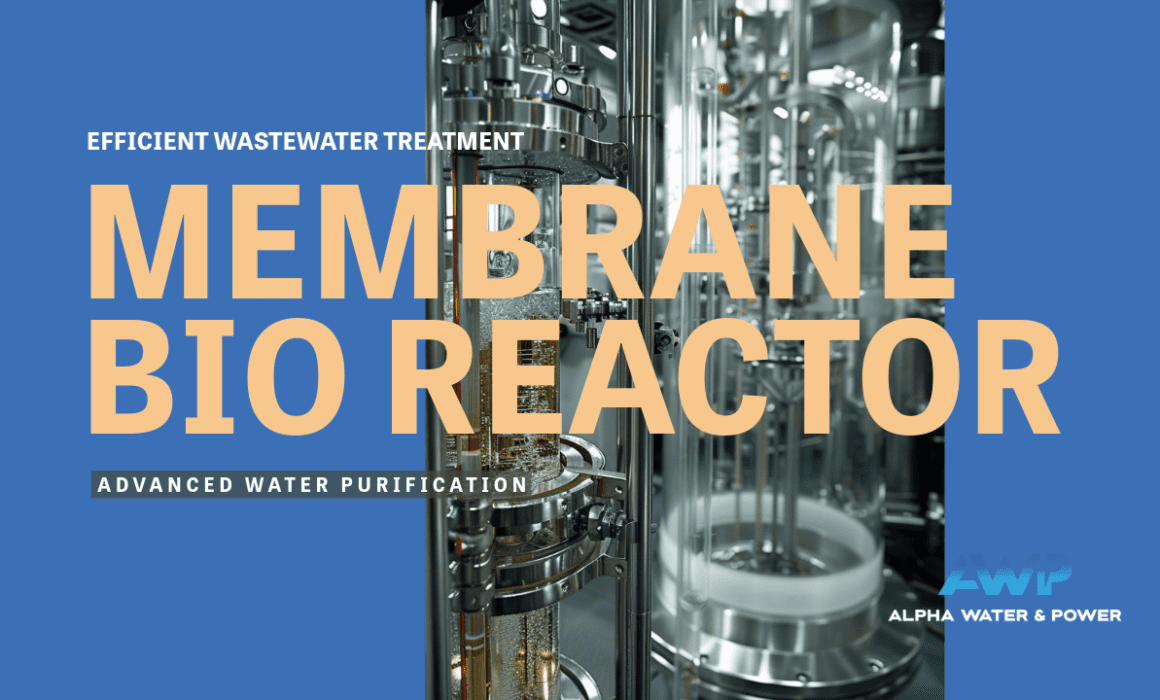

Unveiling Membrane Bio-Reactor Technology: A Modern Solution for Wastewater Treatment

As communities worldwide grapple with the increasing demands of water conservation and wastewater management, advanced technologies such as membrane bio-reactors (MBR) are gaining prominence. This article explores the workings, benefits, and applications of membrane bio-reactor technology, particularly in the context of enhancing wastewater treatment processes.

Introduction to Membrane Bio-Reactor (MBR) Technology

A membrane bio-reactor combines conventional biological treatment processes, like activated sludge, with membrane filtration to provide advanced wastewater treatment solutions. This innovative technology is designed to offer several improvements over traditional wastewater treatment methods, including higher-quality effluent and a more compact footprint.

How Does It Work?

- Biological Treatment: Wastewater enters a bioreactor where microorganisms naturally degrade organic substances.

- Membrane Filtration: The water then passes through a semi-permeable membrane that filters out remaining solids and microorganisms, resulting in clear effluent.

- Effluent Discharge or Reuse: The treated water is either discharged back into the environment, meeting stringent regulatory standards, or reused for various non-potable applications.

Benefits of Using Membrane Bio-Reactors

Membrane bio-reactors offer significant advantages over traditional wastewater treatment methods, making them an attractive option for modern municipal and industrial applications.

Key Benefits:

- Enhanced Effluent Quality: MBR systems produce effluent of higher clarity and lower pathogen levels, which can be safely repurposed, reducing the strain on freshwater resources.

- Space Efficiency: These systems require less space than conventional setups due to the integration of treatment stages and the elimination of secondary clarifiers.

- Operational Flexibility: MBRs operate effectively under a range of conditions and can handle variations in waste load and flow rates, making them suitable for diverse settings.

Applications of Membrane Bio-Reactor Technology

MBR technology is versatile and can be implemented in various sectors where efficient and reliable wastewater treatment is critical.

Key Applications:

- Municipal Wastewater Treatment: Cities adopt MBR systems to upgrade existing wastewater treatment plants and meet tighter effluent quality regulations.

- Industrial Processes: Industries that generate complex wastewater, such as pharmaceuticals and food processing, use MBRs to ensure water quality and facilitate water reuse.

- Developing Regions: MBR systems are increasingly used in developing areas where infrastructure for traditional wastewater treatment is lacking, providing a cost-effective and scalable solution.

Challenges and Future Outlook

Despite their advantages, membrane bio-reactors face challenges such as higher operational costs and membrane fouling. Ongoing research and technological advancements aim to address these issues by improving membrane materials and optimizing system designs.

The future of MBR technology looks promising as it aligns with global trends towards sustainability and water scarcity solutions. Continued innovation and cost reductions are likely to expand its adoption, making MBR a cornerstone of modern wastewater management strategies.

Conclusion

Membrane bio-reactor technology represents a significant step forward in wastewater treatment, offering superior effluent quality, reduced footprint, and greater operational flexibility. As water management becomes an increasingly critical issue, MBR technology provides a viable and effective solution, promising a cleaner, more sustainable future.