The Role of Reverse Osmosis in Wastewater Treatment: Innovations Driving Efficiency and Sustainability

Reverse Osmosis in Wastewater Treatment: Meeting Growing Global Demands

As the demand for water reuse grows, innovations in reverse osmosis (RO) technology are crucial to overcoming challenges like membrane fouling and operational efficiency.

Introduction

Water scarcity and the increasing need for sustainable water reuse have brought the spotlight on reverse osmosis (RO) as a key technology in industrial wastewater treatment. With industries around the world striving to meet production targets while also minimizing their environmental footprint, reverse osmosis systems offer a solution to treat wastewater and produce clean, reusable water.

However, traditional RO systems face significant challenges, particularly membrane fouling, which leads to increased downtime, higher operating costs, and shorter membrane life. As industries search for more effective wastewater treatment solutions, the development of fouling-resistant RO membranes is becoming essential to maintaining stable and efficient operations. This article will explore the role of reverse osmosis in wastewater treatment, the challenges it faces, and how innovations like ZwitterCo’s new fouling-immune membranes are addressing these issues.

What is Reverse Osmosis and Why is it Crucial for Wastewater Treatment?

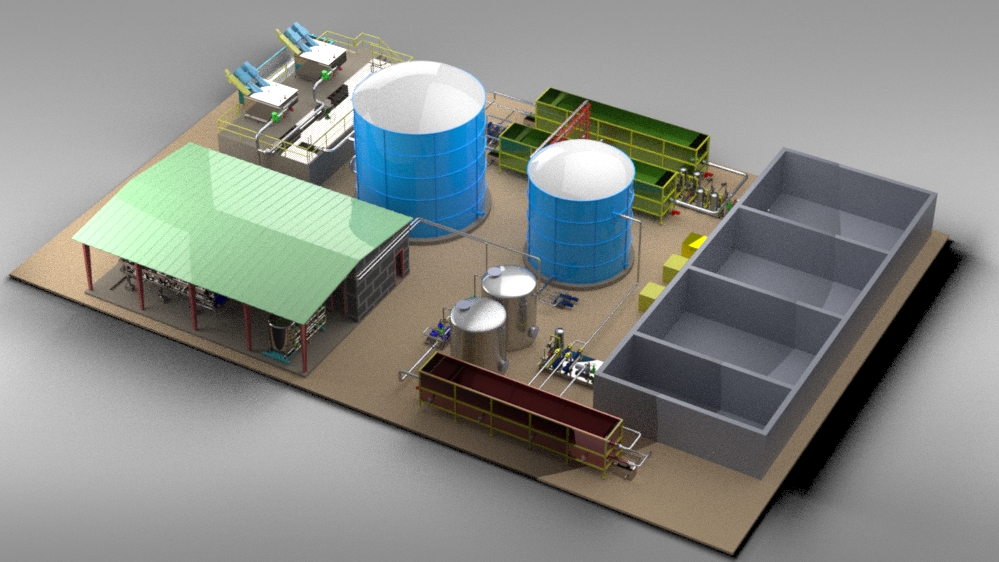

Reverse osmosis (RO) is a water purification process that uses a semi-permeable membrane to remove dissolved salts, organic materials, and other impurities from water. By applying pressure, the process forces water through the membrane, leaving behind contaminants and producing purified water. RO systems are widely used in industries such as power generation, food and beverage, chemical processing, and water desalination, where clean water is critical for operations.

RO plays a pivotal role in wastewater treatment because it enables industries to reclaim water from various wastewater streams, reducing their dependence on freshwater sources. As global freshwater shortages continue to worsen, RO systems offer a sustainable solution by treating billions of gallons of wastewater for reuse annually. These systems are especially vital in regions where water resources are limited, and industries are under pressure to reduce water consumption and meet environmental regulations.

Challenges Facing Traditional Reverse Osmosis Systems

Despite the widespread use of RO technology in wastewater treatment, traditional systems face several operational challenges that can hinder their efficiency. One of the most persistent issues is membrane fouling, particularly from organic and biological contaminants present in industrial wastewater streams.

- Membrane Fouling

Membrane fouling occurs when organic materials, microorganisms, and suspended particles accumulate on the surface of the RO membrane, reducing its performance and increasing the need for cleaning. Organic fouling is particularly common in wastewater treatment, as industrial effluents often contain high levels of organic matter, including oils, greases, and chemicals.

Fouling significantly reduces the effectiveness of the membrane, leading to decreased water production, increased energy consumption, and shorter membrane life. In many cases, operators must perform frequent chemical cleanings to restore membrane performance, which accelerates membrane degradation and increases the frequency of membrane replacements.

- High Operating Costs

Frequent cleanings not only degrade the membrane but also contribute to high operating costs. Each cleaning cycle requires labor, chemicals, energy, and downtime, which can disrupt operations and increase expenses. A study of RO operators in North America found that the median cleaning cost was $43.08 per membrane element per clean. When cleaning is required multiple times per year, these costs can add up quickly, especially for industries with large-scale RO systems.

- System Downtime

Frequent membrane cleanings and replacements also lead to significant system downtime, which can disrupt production and delay critical processes. Industries that rely on continuous water supply, such as power generation and chemical manufacturing, face significant operational challenges when RO systems are offline for cleaning or maintenance.

Innovations in RO Technology: Tackling Fouling and Improving Efficiency

To address these challenges, recent innovations in RO membrane technology are focusing on creating fouling-resistant membranes that can operate efficiently in high-fouling wastewater environments.

Benefits of Advanced RO Membranes for Wastewater Treatment

The development of fouling-resistant RO membranes offers several key benefits for industries looking to improve their wastewater treatment processes and reduce operational costs.

- Reduced Cleaning Frequency

Fewer cleaning cycles result in increased uptime, allowing industries to meet their production targets with less disruption.

In industries like power generation, where maintaining high water quality is crucial for processes such as boiler feedwater treatment, reducing membrane fouling can lead to more reliable operations and lower maintenance costs. Extended cleaning intervals also lead to longer membrane life, reducing the need for frequent replacements and lowering total cost of ownership.

- Lower Operating Costs

By reducing the frequency of chemical cleanings, advanced RO membranes can significantly lower operating costs. Less cleaning means fewer chemicals, less labor, and reduced energy consumption. Additionally, the extended lifespan of the membranes reduces the need for expensive replacements, further lowering operational expenses over time.

In high-fouling applications such as landfill leachate treatment, where traditional membranes may require daily cleanings, the use of fouling-resistant membranes can result in substantial cost savings.

- Improved Sustainability

Beyond the economic benefits, fouling-resistant RO membranes also contribute to improved sustainability in wastewater treatment. By reducing the use of chemicals for cleaning, these membranes minimize the generation of hazardous waste and lower the environmental impact of wastewater treatment operations.

Additionally, by enabling the reuse of treated wastewater, RO systems help industries reduce their reliance on freshwater sources. This is particularly important in regions facing water scarcity, where the ability to recycle and reuse water is critical for both environmental protection and economic development.

Applications of Reverse Osmosis in High-Fouling Environments

Advanced RO membranes are particularly beneficial for industries dealing with high-fouling wastewater or challenging feedwater conditions. Some of the key applications include:

- Power Generation

Power plants require large volumes of purified water for processes such as steam generation and cooling. RO systems are used to treat surface water or wastewater for reuse in these processes. Fouling-resistant membranes help ensure stable water quality, reduce downtime, and minimize the need for frequent membrane replacements.

- Landfill Leachate Treatment

Landfill leachate contains high levels of organic materials, ammonia, and other contaminants, making it a challenging feedwater for RO systems. Fouling-resistant membranes are essential for treating leachate efficiently, reducing cleaning frequency, and ensuring long-term system performance.

- Food and Beverage Industry

The food and beverage industry generates significant amounts of wastewater containing organic materials, oils, and greases. RO systems are used to treat this wastewater for reuse in production processes, reducing water consumption and environmental impact.

Conclusion: The Future of Reverse Osmosis in Wastewater Treatment

The role of reverse osmosis in wastewater treatment is more important than ever as industries face increasing pressure to conserve water and operate more sustainably. While traditional RO systems have been hindered by membrane fouling and high operating costs, recent innovations in membrane technology offer a solution to these challenges.

By reducing the frequency of cleaning, lowering operating costs, and improving system reliability, advanced RO membranes are helping industries optimize their wastewater treatment processes and meet their production goals more efficiently. As the global demand for water reuse continues to grow, reverse osmosis will remain a critical technology for ensuring a sustainable and secure water future.

For Alpha Water & Power, staying at the forefront of these technological advancements is essential for delivering cutting-edge water treatment solutions that address both environmental and industrial challenges.

FAQs

What is reverse osmosis (RO) and how does it work?

Reverse osmosis is a water purification process that uses a semi-permeable membrane to remove impurities from water by applying pressure, forcing water through the membrane while leaving contaminants behind.

Why is reverse osmosis important in wastewater treatment?

RO is crucial for treating wastewater because it enables the recovery and reuse of water, reducing industries’ reliance on freshwater sources and minimizing environmental impact.

What are the challenges faced by traditional RO systems?

Traditional RO systems are often plagued by membrane fouling, which reduces performance, increases cleaning frequency, and leads to higher operating costs and shorter membrane life.