Description

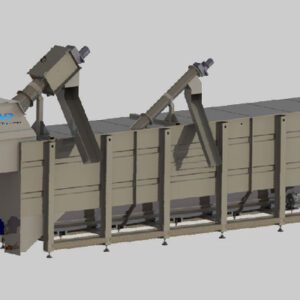

The BU-S is a compact and cost-effective micro combined equipment designed for the pre-treatment of small flow rates of wastewater, handling screenings, grit, and grease removal. This unit is an ideal solution for scenarios requiring a complete pre-treatment process in limited space.

The treatment process begins with the incoming wastewater being filtered through a screw screen. The screen basket in this screw screen is constructed from either perforated plate or wedge wire, ensuring effective filtration.

Following the screening stage, the wastewater enters the settling tank. This tank is specifically designed for high-efficiency grit separation within a small volume, thanks to its fluid dynamic design. An internal baffle system facilitates the efficient separation of sand, which is then collected at the bottom of the tank and removed by the spiral conveyor.

The BU-S unit is available in two configurations:

- The CBUS – 3: This configuration provides a complete treatment solution, including screening, grit, and oil/grease separation. It features a specially designed grease removing system for the removal of floating matters (FOG). Typically, this unit includes a blower to enhance both grit separation and FOG removal.

- The CBUS – 2: This configuration is focused on wastewater screening and grit separation.

Manufacturing materials for the BU-S unit include stainless steel (grades 304 or 316) for the main body, with the spiral component available in either carbon steel or stainless steel, or a combination of these materials to suit various application needs.

Key advantages of the BU-S system include:

- High operational efficiency.

- Simplicity in design and function.

- Extremely easy installation and maintenance.

To meet specific operational requirements, the unit can be equipped with a control panel upon request, available in either electromechanical or PLC-controlled formats.