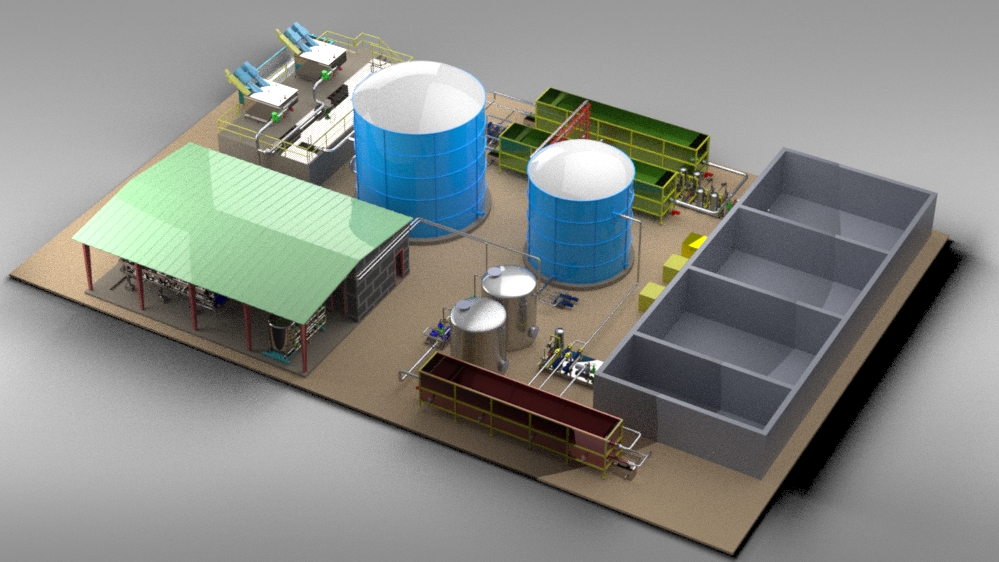

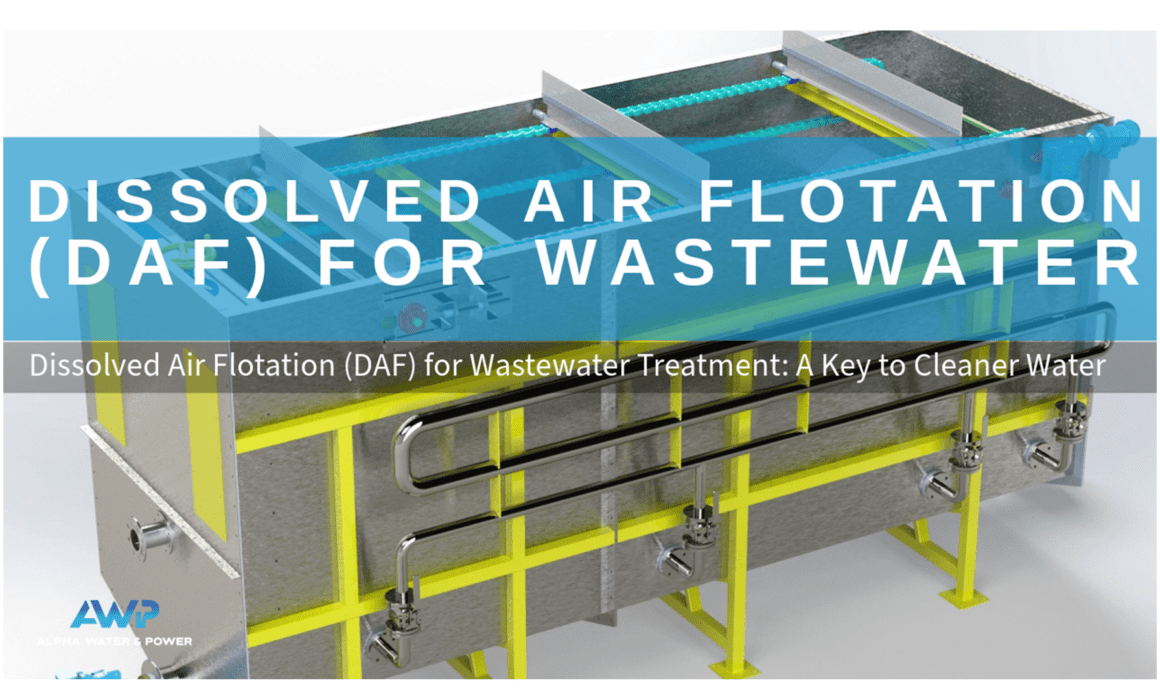

Dissolved Air Flotation (DAF) for Wastewater Treatment: Revolutionizing Water Purification

Wastewater treatment is an essential process that ensures the safe disposal or reuse of water after it has been used for industrial, commercial, or residential purposes. One of the most effective and widely used technologies in modern wastewater treatment is Dissolved Air Flotation (DAF). This system helps remove suspended solids, oils, and other contaminants from wastewater, offering a highly efficient method of purification. As urbanization and industrialization continue to grow, the demand for advanced wastewater treatment solutions like DAF is more critical than ever.

In this article, we will explore how DAF systems work, their benefits, and why they have become an integral part of wastewater treatment for companies like Alpha Water & Power.

What is Dissolved Air Flotation (DAF)?

Dissolved Air Flotation (DAF) is a water treatment process that removes suspended particles, such as oils, greases, and solids, from wastewater by using micro-bubbles of air. The process leverages the principle of flotation, where lighter particles float to the surface due to the action of the air bubbles, making it easier to skim off impurities and produce cleaner water.

How DAF Systems Work

The DAF process involves several stages, which make it highly effective at separating contaminants from wastewater:

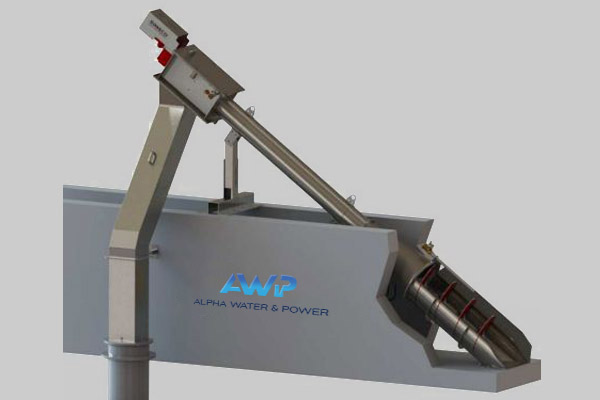

- Pre-treatment: Before the water enters the DAF unit, it typically undergoes some form of pre-treatment to remove large debris and reduce heavy loads of contaminants. This step helps to improve the efficiency of the DAF system.

- Pressurization and Saturation: The wastewater is mixed with air under high pressure, creating a supersaturated solution. This pressurized mixture is then released into the flotation tank, where the pressure is reduced.

- Air Bubble Formation: When the pressure drops, the dissolved air forms tiny micro-bubbles that attach to suspended particles in the water. These bubbles help lift the contaminants to the surface by reducing their overall density.

- Skimming and Removal: As the particles float to the surface, a mechanical skimmer collects the sludge, which is then removed from the system. The cleaned water exits from the bottom of the flotation tank.

DAF systems are particularly effective at removing a wide range of contaminants, including fats, oils, grease (FOG), suspended solids, and biological matter, which can otherwise be difficult to treat using traditional methods.

Benefits of DAF in Wastewater Treatment

DAF systems offer several advantages that make them a preferred choice for wastewater treatment across various industries. These benefits include improved efficiency, cost-effectiveness, and environmental sustainability.

- High Removal Efficiency

One of the primary reasons DAF is widely used is its exceptional ability to remove suspended particles, oils, and grease from wastewater. The process can achieve removal rates of up to 99% for certain contaminants, making it ideal for industries where wastewater contains high concentrations of fats, oils, and suspended solids. DAF is particularly effective for industries like food processing, petrochemicals, and manufacturing, where wastewater often contains these hard-to-treat materials.

- Versatility Across Applications

DAF systems are versatile and can be customized to handle different types of wastewater with varying levels of contaminants. Whether the treatment involves industrial effluent, municipal wastewater, or the oil and gas sector, DAF units can be adapted to meet the specific needs of the application. This versatility allows industries to treat their wastewater to meet stringent discharge standards or prepare it for reuse, improving water sustainability.

- Compact Design and Space Efficiency

Compared to other water treatment technologies, DAF systems offer a relatively compact footprint. This space efficiency makes DAF an attractive option for facilities with limited space for wastewater treatment operations. The system can be installed in smaller areas while still delivering high performance in terms of water purification.

- Cost-Effective Operation

While the initial setup costs for a DAF system can be higher than traditional wastewater treatment systems, the long-term savings on operational costs make it highly cost-effective. DAF requires less energy to operate than other processes, such as sedimentation or filtration, and the high efficiency of contaminant removal can reduce the need for additional treatment stages. Additionally, by efficiently treating wastewater and recovering water for reuse, industries can cut down on water consumption costs.

- Environmental Sustainability

DAF technology plays a crucial role in supporting environmental sustainability. By removing pollutants such as oils, grease, and suspended solids, DAF systems help reduce the impact of industrial wastewater on aquatic ecosystems and water bodies. Additionally, industries that implement DAF systems often reuse treated water, reducing the overall demand for freshwater resources. This is especially important in regions facing water scarcity or where water conservation is a critical concern.

Applications of DAF in Various Industries

DAF technology has broad applications across different industries due to its ability to treat a wide variety of wastewater streams. Some of the most common industries that rely on DAF systems for wastewater treatment include:

- Food and Beverage Industry

In the food and beverage sector, wastewater often contains high levels of fats, oils, grease, and organic matter. DAF systems are particularly effective in this industry, as they can remove these contaminants efficiently, allowing companies to meet discharge regulations or prepare the water for reuse.

- Oil and Gas

The oil and gas industry produces wastewater containing hydrocarbons, oils, and solids that must be treated before being discharged or reused. DAF systems are well-suited for separating oil and other contaminants from water in these applications, ensuring compliance with environmental regulations.

- Pulp and Paper Industry

The pulp and paper industry generates large volumes of wastewater that contain suspended solids, organic matter, and chemicals. DAF technology is used to treat this wastewater, reducing the levels of contaminants and allowing the water to be safely discharged or recycled.

- Municipal Wastewater Treatment

Municipal wastewater treatment plants use DAF systems to remove suspended solids and other impurities from water before it is released into rivers, lakes, or oceans. DAF technology plays a vital role in ensuring that municipal water treatment processes meet environmental standards for safe discharge

.

- Textile and Manufacturing

Wastewater from textile and manufacturing industries often contains dyes, chemicals, and solid particles that require specialized treatment. DAF technology helps to remove these pollutants, making it easier to meet discharge regulations and reduce the environmental impact of industrial wastewater.

Why Alpha Water & Power Embraces DAF Technology

As a leading provider of water and wastewater treatment solutions, Alpha Water & Power recognizes the importance of using advanced technologies like Dissolved Air Flotation (DAF) to address the growing challenges of water scarcity and pollution. By incorporating DAF systems into their treatment processes, Alpha Water & Power ensures that industrial and municipal clients have access to efficient and reliable wastewater treatment solutions that align with environmental sustainability goals.

Commitment to Sustainability

Alpha Water & Power is committed to promoting sustainable water management practices. By utilizing DAF systems, the company helps industries reduce their environmental footprint by minimizing the pollutants released into natural water bodies and promoting the reuse of treated water. This commitment to sustainability benefits both the environment and the industries they serve.

Innovative Solutions for Growing Demands

As the demand for clean water continues to rise, Alpha Water & Power remains at the forefront of innovation by integrating cutting-edge technologies like DAF. The company provides customized solutions that meet the unique needs of each client, ensuring optimal performance and cost-efficiency in wastewater treatment operations.

Conclusion: The Future of Wastewater Treatment with DAF

Dissolved Air Flotation (DAF) is a game-changer in the field of wastewater treatment. Its ability to efficiently remove suspended solids, oils, and grease makes it an invaluable tool for industries seeking to reduce their environmental impact and ensure compliance with stringent water quality standards. As the world grapples with water scarcity and pollution, DAF systems will continue to play a crucial role in safeguarding our water resources and promoting sustainable industrial practices.

With companies like Alpha Water & Power leading the way in adopting advanced technologies like DAF, the future of wastewater treatment looks promising. Cleaner water means a healthier planet—and DAF systems are at the heart of making that vision a reality.